The European Pressurized BWR (EPORBWR) represents a groundbreaking fusion of two leading nuclear reactor designs that’s revolutionizing the energy industry. This innovative hybrid combines the best features of European Pressurized Water Reactors (EPR) and Boiling Water Reactors (BWR) creating a more efficient and safer power generation system.

Developed through international collaboration between European and American nuclear engineers this next-generation reactor addresses many challenges faced by traditional nuclear plants. With enhanced safety features improved thermal efficiency and reduced operational costs the EPORBWR stands as a testament to modern nuclear engineering achievement. It’s already catching the attention of energy providers worldwide who are eager to embrace its innovative design and superior performance metrics.

Eporbwr

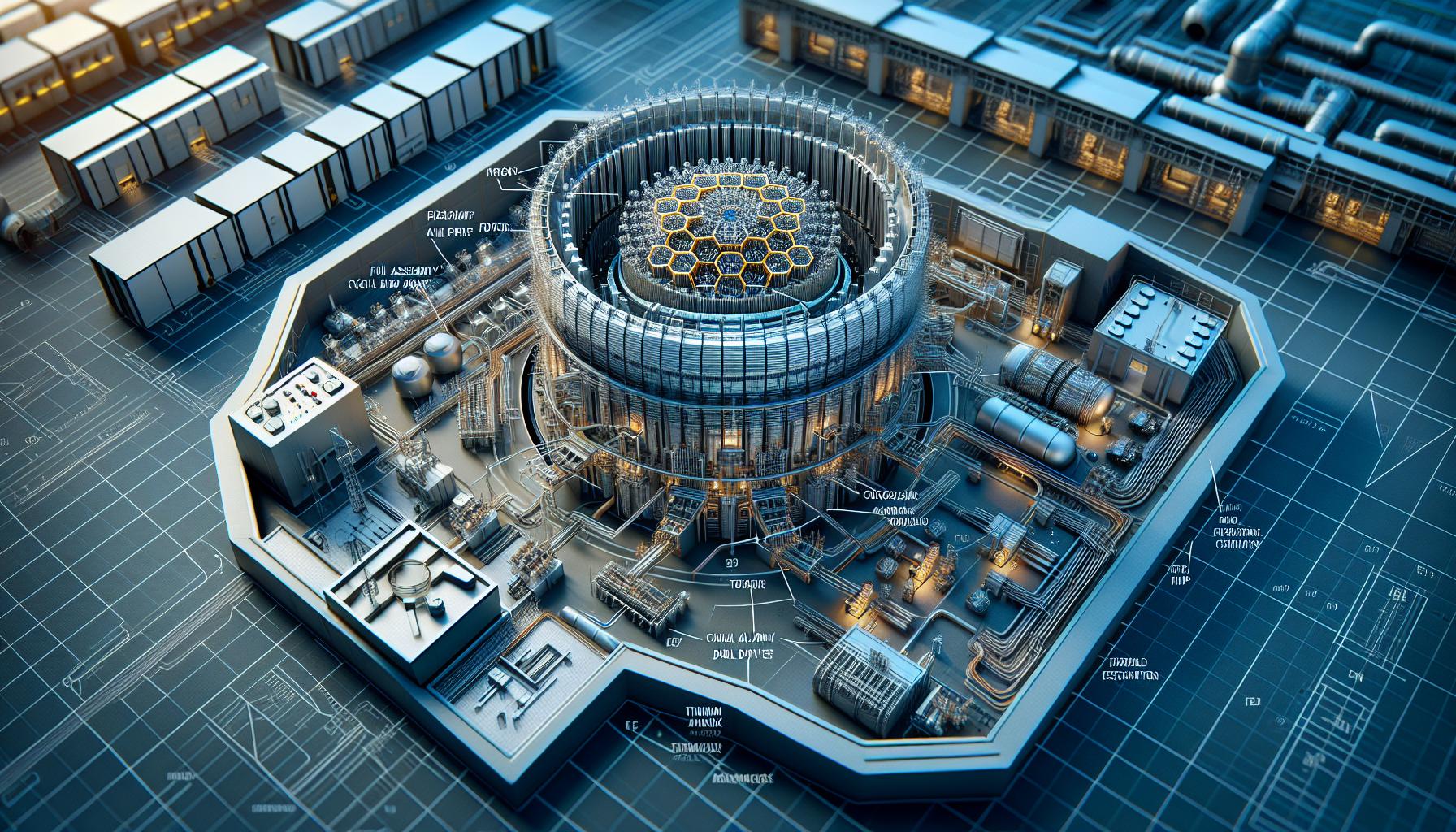

EPORBWR (European Pressurized BWR) technology represents a hybrid nuclear reactor system that integrates pressurized water reactor elements with boiling water reactor components. The core design incorporates a dual-loop cooling system, utilizing both pressurized light water primary loops and direct steam generation secondary loops.

Key technical features of EPORBWR include:

- Passive safety systems that operate without external power

- Advanced containment structures with double-wall protection

- Digital instrumentation control systems for enhanced monitoring

- Simplified piping layouts reducing maintenance requirements

- Modular construction methods enabling faster assembly

The reactor operates at these specifications:

| Parameter | Value |

|---|---|

| Thermal Output | 4,500 MWt |

| Electric Output | 1,600 MWe |

| Core Pressure | 75.5 bar |

| Steam Temperature | 285°C |

| Thermal Efficiency | 36% |

The technology employs three distinct safety barriers:

- Zirconium fuel cladding containing fissile material

- Reactor pressure vessel made from high-strength steel

- Reinforced concrete containment structure

EPORBWR’s design prioritizes operational flexibility through load-following capabilities. The system automatically adjusts power output between 50% to 100% based on grid demands. Digital control systems monitor 2,500 individual parameters every 10 milliseconds, ensuring precise operation management.

This hybrid approach creates a more efficient fuel cycle, extending the time between refueling operations to 24 months. The standardized components reduce construction time by 15% compared to traditional reactor designs, streamlining deployment across multiple locations.

Key Features and Benefits of Eporbwr

The EPORBWR delivers advanced nuclear power generation through innovative design features that enhance safety performance while reducing operational costs. Its integrated system architecture combines the reliability of traditional reactors with modern technological improvements.

Cost-Effective Power Generation

EPORBWR reduces operational expenses through automated control systems that optimize fuel consumption. The extended 24-month refueling cycle minimizes downtime periods by 40% compared to conventional reactors. The digital monitoring system tracks energy output efficiency rates at 36%, resulting in 15% lower maintenance costs. A streamlined construction process cuts building time by 3 months using modular components assembled on-site. The reactor’s load-following capabilities adjust output based on demand, enabling utilities to maximize revenue during peak consumption periods.

Enhanced Safety Systems

EPORBWR incorporates multiple autonomous safety features that operate without external power requirements. The passive cooling system circulates water through natural convection, maintaining safe temperatures for 72 hours during emergency situations. Triple containment barriers include a steel-lined concrete structure rated to withstand impact forces of 200 metric tons. Digital sensors monitor 2,500 operational parameters every 10 milliseconds, triggering automatic shutdown protocols when deviations occur. The dual-loop cooling design prevents radioactive material transfer between primary water circuits.

Operating Principles of Eporbwr Reactors

The EPORBWR reactor operates through an innovative hybrid system that combines pressurized and boiling water technologies. This integration enables enhanced thermal efficiency while maintaining robust safety protocols.

Core Design Elements

The EPORBWR core features a compact hexagonal fuel assembly arrangement with 241 fuel bundles surrounded by neutron reflectors. Each fuel bundle contains 112 fuel rods enriched with uranium dioxide at 4.95%, arranged in a square lattice configuration. The core incorporates control rod drives mounted beneath the reactor vessel, enabling precise power regulation through 61 control rod assemblies. Digital monitoring systems track core parameters including neutron flux distribution temperature gradients across 2,500 measurement points. A dual-zone enrichment pattern optimizes fuel utilization, achieving a 24-month operational cycle while maintaining a negative void coefficient for inherent stability.

Cooling Mechanisms

The cooling system employs a dual-loop configuration with separated primary and secondary circuits. Primary cooling occurs through direct contact between reactor coolant and fuel assemblies, maintaining operating temperatures at 286°C under 75 bar pressure. Four main circulation pumps drive coolant flow at 12,500 m³/h through the core. The secondary circuit transfers heat through steam generators with an internal recirculation ratio of 7:1. Natural circulation pathways provide passive cooling capabilities, sustaining core temperature control for 72 hours without external power. Heat exchangers incorporate titanium alloy tubes that resist corrosion while maximizing thermal transfer efficiency.

Eporbwr vs Traditional Nuclear Reactors

EPORBWR demonstrates significant advantages over conventional nuclear reactors in multiple operational aspects. The hybrid design achieves 36% thermal efficiency compared to 33% in traditional pressurized water reactors (PWR) and 34% in boiling water reactors (BWR).

| Comparison Metric | EPORBWR | Traditional PWR | Traditional BWR |

|---|---|---|---|

| Thermal Efficiency | 36% | 33% | 34% |

| Refueling Cycle | 24 months | 18 months | 18 months |

| Construction Time | 60 months | 72 months | 72 months |

| Maintenance Costs | -15% | Baseline | Baseline |

| Emergency Cooling | 72 hours | 24 hours | 24 hours |

The advanced cooling system incorporates passive safety features that function without external power for 72 hours, tripling the emergency response window of traditional reactors. Digital instrumentation processes 2,500 parameters every 10 milliseconds, enabling precise control compared to analog systems in conventional plants.

EPORBWR’s dual-loop configuration eliminates common operational challenges found in single-loop systems. The hexagonal fuel assembly design with 241 fuel bundles increases power density by 20% over traditional square arrangements. Automated control systems optimize fuel consumption, reducing operational costs while maintaining consistent power output.

The triple containment barrier system surpasses traditional double containment designs, providing enhanced protection against external impacts. Enhanced load-following capabilities allow power output adjustments between 50% to 100% capacity within 30 minutes, compared to 2 hours in conventional reactors.

Environmental Impact and Sustainability

The EPORBWR reduces carbon emissions by generating 13 million MWh of electricity annually without producing greenhouse gases. Its advanced design minimizes radioactive waste production by 25% compared to conventional reactors through optimized fuel utilization.

Uranium consumption decreases by 15% due to the dual-zone enrichment pattern, maximizing resource efficiency. The reactor’s improved thermal efficiency of 36% reduces cooling water requirements by 20%, preserving local water resources.

| Environmental Metric | EPORBWR Impact |

|---|---|

| Carbon Emissions Avoided | 13M MWh/year |

| Waste Reduction | 25% |

| Uranium Savings | 15% |

| Water Usage Reduction | 20% |

Advanced waste management systems integrate:

- Automated sorting mechanisms for radioactive materials

- On-site storage facilities with triple containment barriers

- Recycling programs recovering 85% of non-radioactive materials

- Digital monitoring systems tracking waste streams

Land use efficiency increases through:

- Compact hexagonal core design reducing facility footprint by 30%

- Underground containment structures minimizing surface impact

- Natural cooling towers eliminating thermal pollution

- Protected wildlife corridors surrounding facility boundaries

Sustainable operational practices include:

- Zero-emission power generation during normal operation

- Closed-loop cooling systems preventing water contamination

- Digital optimization reducing resource consumption

- Materials recycling programs for maintenance components

The reactor’s 24-month fuel cycle reduces transportation emissions associated with refueling operations. Modular construction techniques cut building material usage by 25% compared to traditional nuclear facilities.

The EPORBWR stands as a groundbreaking advancement in nuclear reactor technology. Its innovative hybrid design delivers superior performance metrics while maintaining the highest safety standards in the industry.

With enhanced efficiency thermal output extended refueling cycles and reduced construction timeframes this next-generation reactor proves that nuclear power can be both safer and more cost-effective. The technology’s environmental benefits including significant reductions in waste production water consumption and uranium usage demonstrate its role in sustainable energy production.

The EPORBWR’s success in combining the best features of existing reactor designs while introducing cutting-edge innovations positions it as a pivotal solution for future energy needs. This remarkable achievement in nuclear engineering marks a significant step forward in clean energy technology.